TYRE SELECTOR

Find your perfect tyre fast…

Our Services & Process

Tyre Inspection

All casings undergo a thorough examination. A visual examination is followed by shearography inspection, in addition casings are checked for nail holes with state of the art detector equipment, this detects inner liner and casing perforations in crown and sidewall.

Pressure Check

All tyres are pressured checked to ensure safety and fuel efficiency.

Get to the heart of your tyres

To ensure that a retread tyre will offer the best possible performance, any defects must be identified. One of the most common defects in a radial tyre are separations within the casings, particularly in super singles due to the high level of lateral scrub. Unfortunately, these are also the hardest to find, as they are often deep within the belt construction under the tread.

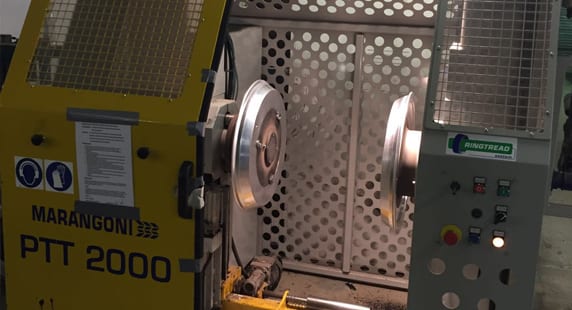

Vulcanisation

Vulcanisation takes place in the latest segmented tyre presses, which allows curing and tread moulding to take place with minimum distortion of the casing.

Bead to Bead Remoulds

New sidewall veneer is automatically applied prior to building the new tread. A computerised tyre builder extrudes the unique high mileage compound in a continuous ribbon onto the casing. This ensures every tyre is manufactured to precise profile dimensions and weight.

Buffing and Preparation

The old tread is removed using a computerised buffing machine. This will automatically reduce the casing to the exact diameter, profile and surface texture required. The casing is then inspected and damages removed, cleaned and rebuilt to precise tolerances.

Our Blog

The latest news from Truck Tyre Specialists

COMPRESSOR PROCUREMENT – TENDERS INVITED

Project: New 15 Bar 10 m3/min air compressor renewal. Specifications: We are renewing our 2 old...

[ READ MORE ]New Compressor Tender 19-08-2022

Opportunity to supply and install a 15 bar 10.04 m3/min (75-355 cfm) screw compressor. This...

[ READ MORE ]VERY SAD LOSS

It is with much sadness and sorrow that we have lost one of our founders Robert Collins on...

[ READ MORE ]BUFFING HIGH – 2021 INVESTMENT PROGRAM UNDER WAY

Our new state of the art casing buffing machine has arrived and we are very excited! This is...

[ READ MORE ]Building On Our Past To Build The Future

Truck Tyre Specialists are pleased and proud to announce the purchase of a new state of the art...

[ READ MORE ]435/50R19.5 RTA-E Mega Cube Trailer Tyre

We are pleased to announce that we have added the super wide low profile mega cube 435/50R19.5...

[ READ MORE ]